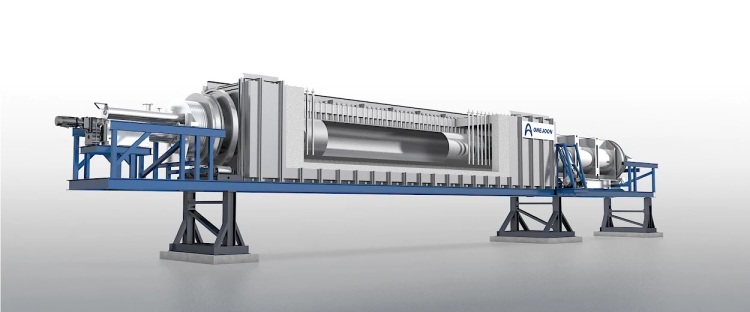

Rotary Kilns

Rotary dryers and coolers can be installed as standalone units or Complete systems deliveries including PLC, Dust Collection, Product Conveying (Feed and Discharge) Exhaust Gas Handling, Heat Exchanging, and Fuel Delivery Systems

Mechanical simplicity

Continuous operation

Low maintenance

Number of industries served

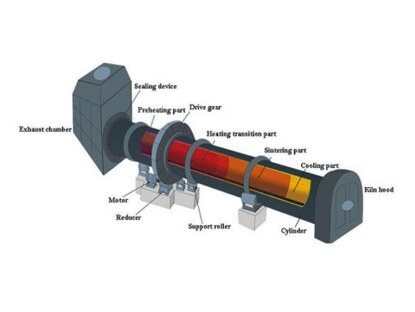

How it works?

The Rotary Drying and Cooling equipment utilizes a hot gas stream or cold gas stream that mixes with the product. The product is mixed with the air stream by utilizing lifters that shower the product in the air stream. The mechanical lifting aides in breaking clumps, which aides in the drying process. The equipment is set on an incline and conveys material down the cylindrical shaft.

Rotary Drying and Cooling is used in a wide variety of applications and industries where there is a need for a large throughput of material to be processed. The Rotary equipment is suited for different sized particles, large and small, and different moistures as well. Product temperatures can be easily controlled in the equipment, and the process know how of Metso allows for a consistent process product.

Applicable industries:

- Mineral and Coal applications

- Iron Ore

- Plastic and Polymer

- Limestone

- Potash & Phosphate Industries

- Rare Earth Elements

- Sodium & Salts

- Clays

- Wood FIber and Wood Chips

- Yellow Cake

- Waste sludge