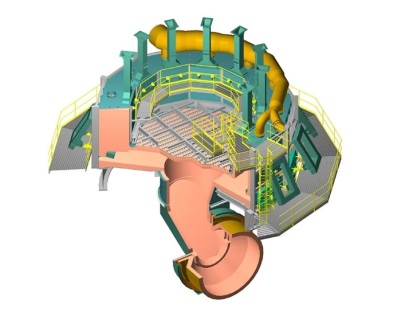

Annular Coolers

Annular cooler is main equipment for the pelletizing and sintering process, it is common equipment in this industry. It is widely used for sinter and pellet cooling. There are two main functions: cooling high temperature oxidation pellet which discharged from kiln, to ensure the temperature low enough and satisfy to subsequent process; as the key point of thermal equilibrium for whole system, it recycles quantity of heat which is from high temperature pellet, and it used for previous process thereby reducing the fuel consumption.

FEATURES

Although the major elements of the process reside in the grate and kiln, a cooler is added to the system.

Recuperates heat from the pellets in both the primary and final cooling zones

Cool the pellets to a temperature for safe handling

BENEFITS

Proper operation of the cooler with respect to the grate and kiln will result in significant fuel savings.

The cooler is an integral part of a total process consisting of a traveling grate preheater, a rotary kiln and a cooler.

Process description

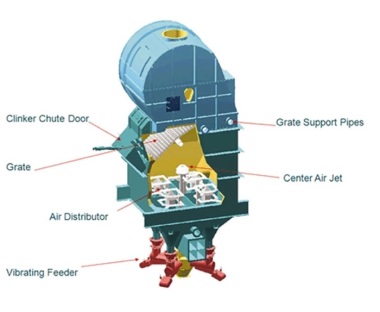

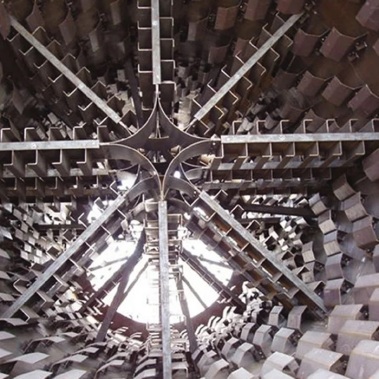

An annular cooler is a turntable that holds the hot pellets. The ambient air is blown through the hot pellets. The turntable is made of wedge shaped pans. The pellets fall out of the kiln directly onto the pans. The pellets travel all around the turntable until the pan is tipped and the pellets fall underneath. The pan is then righted to accept more material. The cooler pans are supported by rollers. Each of these rollers require lubrication. It is for this reason that advance lubrication systems are developed.

Applications: Iron ore pelletizing